Innovation often comes from applying knowledge from one field to another one which is totally unrelated. This is exactly what happened with this modular wonder.

The Wikkelhouse was designed and built by a small Company in Amsterdam that started up as a theatre scenery Company in 1989.

You can fall in love with it at first sight.

The simplicity of its design is overwhelming, yet fascinating. The full-width glass facade screams modern while the round features make you think high-quality and excellent craftsmanship.

Looking at it from the side, it is evident that this is a modular building. The 1.2m wide sections are clearly visible as no attempt was made to hide the separation line between the modules.

The Wikkelhouse comes in visible segments, with no shame whatsoever.

Wikkelhouses in Stayokay campsite.

Wikkelhouse in Stayokay campsite.

Wikkelhouse in Stayokay campsite - closeup of the entrance.

Wikkelhouse in Rotterdam Red Apple Marina.

The interior is as good as it gets.

Smooth plywood shets wrap around the entire building envelope and give the house a unique look that feels premium and solid.

Even from the inside, the separation lines between the modules are clearly visible and this adds depth to the interior space. In theory, there is no limit to the number of modules (segments) you can add.

This calls for a very loooooooong house!

On top of the exceptional look and unlimited expandability, the clever Dutch people at Fiction Factory came up with a specialized module for the bathroom and one with the round window, plus accessories for kitchen, living room and stove.

This allows putting together a personalized version of the Wikkelhouse.

Wikkelhouse interior.

Wikkelhouse interior - kitchen module.

Wikkelhouse interior - living room.

Wikkelhouse interior - large living room.

Wikkelhouse interior - stove.

Wikkelhouse - the full system.

This modular concept is super simple and yet truly remarkable.

The entire house is installed on a chassis made of concrete blocks and wooden beams. The house is very lightweight (more on that in a moment) and, thanks to this particular characteristic, the chassis can be placed on leveled and compacted ground, requiring no foundations.

This cuts down installation costs and installation time.

High-five to Dutch inventors!

Now, the truly remarkable innovation here is another one:

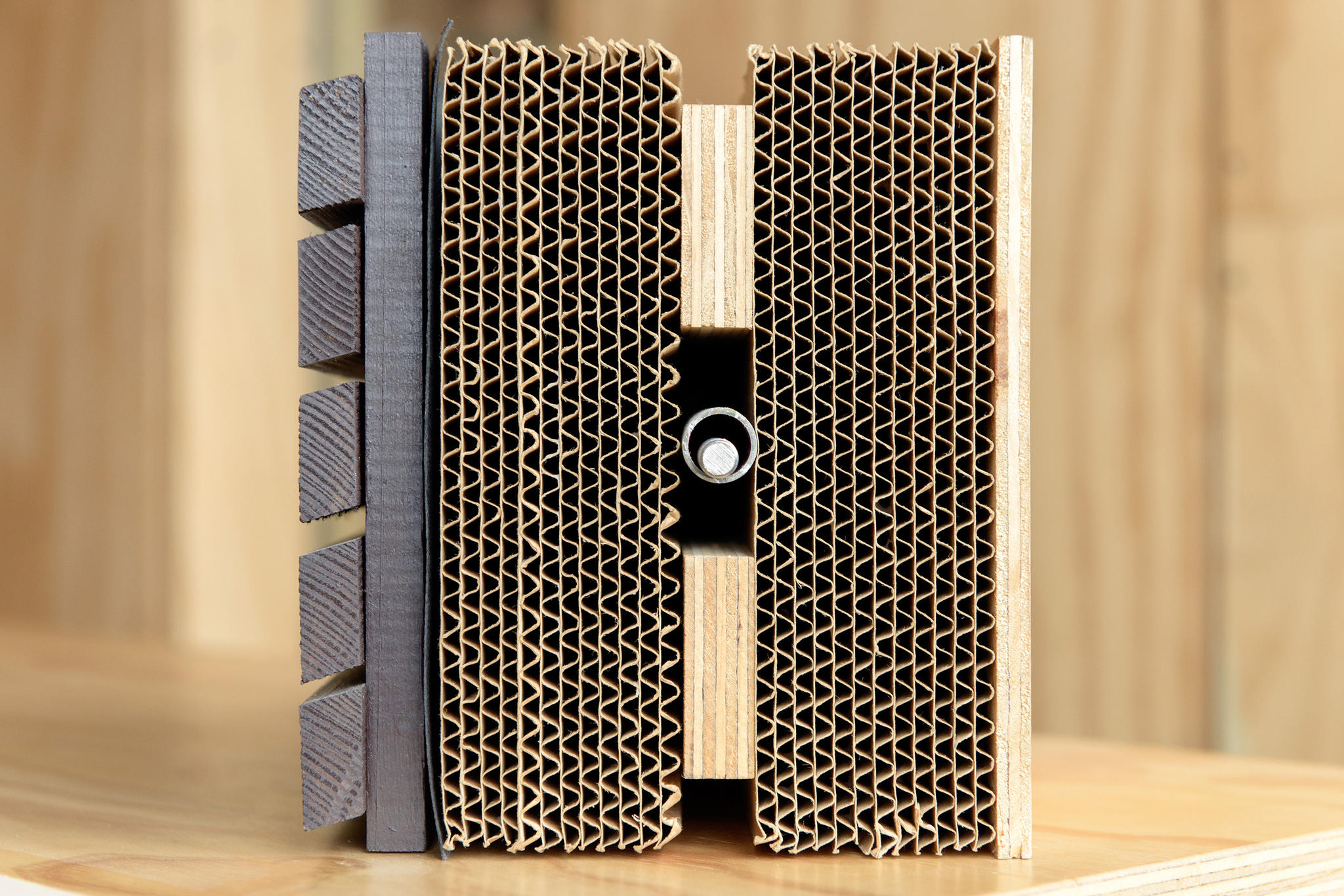

this house is made of cardboard!

Believe it or not, each segment is built by "rolling" a tiny sheet of cardboard over a steel framework.

The entire system is absolutely ingenious!

The Manufacturer declares a wall U-value of approximately 0.29 W/m2K (R = 3.5).

U-value of windows is declared as 0.24 W/m2K (R = 4.2).

Wikkelhouse - section of the cardboard wall.

The 1.2m wide cardboard sheet is wrapped around the framework while 60 lines of glue are "drawn" on the sheet. The glue sticks the layers together and bonds the entire structure as a solid block.

Once the glue has hardened, the steel framework is removed and the segment is ready for finishing.

Wikkelhouse - cardboard gluing.

Wikkelhouse - rolling of the cardboard wall.

The main characteristics of the Wikkelhouse, as described by the Producer, are:

- 100% recyclable;

- 3X more eco-friendly than traditional houses;

- exceptional constructive strength;

- optimal insulation qualities;

- unequaled acoustics;

- expected life-cycle of 50 years minimum;

- no foundation needed.

While that's just about anything one would want from a modern prefab house, the Wikkelhouse has another strong selling point: the price.

According to the Producer, a three segments house can be purchased for 30 000 EUR (VAT, transport, installation excluded).

Given the measurements (4.6 x 1.2 x 3), such house would have an indoor net area of approximately 16.6 square meters... setting the square meter price to an unprecedented 1812 EUR per square meter.

For comparison, the concrete built KODA by Kodasema sells for about 3700 EUR per square meter while the glamorous ÖÖD Airbnb module by ÖÖD OÜ sells for about 2500 EUR per square meter.

It really seems The Netherlands are going to beat Estonia with ease... or maybe not (spoiler alert: you cannot get the Wikkelhouse so easily).

Wikkelhouse - view of one segment (module).

Wikkelhouse - assembling of the bathroom module.

The transport of a Wikkelhouse is a relatively simple matter.

Thanks to the standard size of the modules of 1.2m, two modules can be transported side by side, amounting to a total depth of 2.4m. The set of two modules fits perfectly on a standard truck (see image below).

Widthwise, one standard trailer can also carry two modules (see image below).

Overall, up to four modules can be loaded onto one standard truck.

The size of a Wikkelhouse composed by four module would be 4.6 x 1.2 x 4 = 22.08 square meters.

Wikkelhouse - transport of four segments.

Once on site, the modules can be unloaded with a regular fork-lift and placed directly onto the foundation chassis.

The operation is quite simple and, unlike most modular systems, it does not require a crane.

Wikkelhouse - lifting one segment.

Wikkelhouse - installation of segments on-site.

Once in place, the modules are secured into place and the structure is finished from the outside with the addition of the wooden cladding.

Once assembled, the house is already finished on the inside and the owner can immediately move in.

Wikkelhouse - installation detail.

This modular system comes indeed with a number of advantages:

- ease of transport;

- reasonable cost per square meter;

- beautiful modern design;

- functionality;

- scalability.

The only disadvantages seem to be the availability and the fact that you cannot customize the architecture of the house.

The only things you can customize are minor details like colors and presence of windows but the shape of modules is fixed and they can only be assembled in a straight line (so far).

The availability represents the major downside of this otherwise spectacular piece of engineering.

At the moment of writing the Wikkelhouse is available only in the following Countries:

- the Netherlands

- Belgium

- Luxembourg

- France

- Germany

- the U.K

- Denmark.

The Manufacturer claims this is due to transport and installation costs. We are a bit skeptic about that and we tend to believe it is more of a marketing move.

In fact, Fiction Factory decided to play the scarcity card, manufacturing only 20 houses per year.

This is clearly stated on their home page.

Wikkelhouse - screenshot of waiting list from wikkelhouse.com.

So, if you do fall in love with this modular system, you probably will have to wait more than one year to get it... even if money is not an issue!

Fiction Factory employes 45 full-time craftsmen and perhaps this "limited availability business model" is a first attempt to assess their peak production capacity.

We would like to believe that once they figure out which is the real demand for the product and which is their real production capacity, they will start to manufacture more houses... so that one can order the house and get it in a few weeks like it happens for any other factory made product.

Perhaps we'll see this happen... together with a sensible raise of the price.

We'll be here ready to cover their progress with an update.

Photo Credits (all photos): Yvonne Witte.